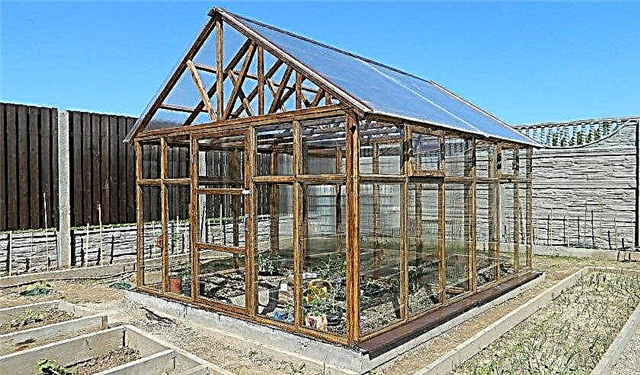

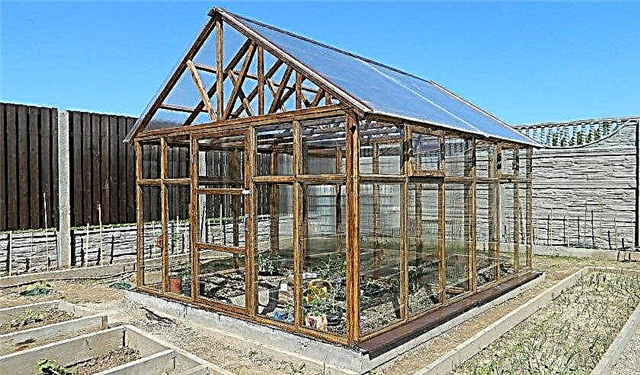

Wood is an environmentally friendly and durable material from which both capital and temporary structures are erected. Greenhouses are no exception: it is very simple to erect them from such material. Let's consider in the article the basic principles of building greenhouses from wood.

The advantages of wooden greenhouses

- The wooden structure has the following advantages:

- cheapness - quality material at an affordable price is easy to find;

- simplicity - work with a tree does not have particular difficulties, damaged construction details are easy to replace;

- environmental friendliness - is a "breathing" material;

- simplicity in assembly - any material is easy to attach to a wooden structure;

- easy dismantling - if necessary, the wooden greenhouse can be easily disassembled, and then reassembled;

- unlimited in size and shape - the tree allows you to create any design;

- low maintenance - after treatment with moisture repellents, the finished structure does not need to be maintained.

Varieties of wooden frames

As already noted, the tree allows you to complete the construction of any size and shape, so the variety of wooden greenhouses is amazing. Among them there are some options that combine functionality and ease of construction.

These include:

- Gable roof frame. The most popular and easiest option. It has the appearance of a rectangle and a roof with a slope of the slope of not more than 30 °. Film and glass are suitable for their shelter. Polycarbonate is not profitable to use, since a lot of residues are obtained.

- Arched type. This design is most effective for heating (there is no stagnation of air in the corners), which means that maintaining the optimum temperature is easier. To cover it, it is best to use polycarbonate.

- Pent roof. This construction option is most suitable as a wall, which allows for good thermal insulation. Its installation is very simple, since the base is attached to the capital building. For shelter you can use any material.

- Ball construction. It is difficult to mount a round structure, since there are many details and joints. But such a structure is well lit, it is easy to heat it. You can cover the frame with a film or polycarbonate.

- Mitlider construction. The frame has a shape similar to a simple gable greenhouse, but its slopes do not close in the ridge and have a different angle of inclination.

Did you know? Thanks to Peter I, greenhouses were brought to Russia. After the construction of St. Petersburg, he ordered a Pharmaceutical Garden to be planted there, where medicinal plants for citizens and exotic plants were grown.

How to build a greenhouse from a tree with your own hands

So that during the construction process there are no problems, you must first determine the type of frame and dimensions of the building. Based on this, a diagram should be drawn up, a drawing of the product, on it to calculate the necessary materials. After that, you can start building.

Selection and preparation of materials

Wooden blocks can be:

- from larch;

- from spruce;

- from pine;

- glued.

The cheapest option would be to use spruce beams. But the installation of such material is fraught with some difficulties, namely, the processing of timber for protection against decay. Larch does not need additional processing, but its price is high.

Video: Budget greenhouse made of timber

The glued beam stands apart here - it is not a product of one wood species, but a kind of composite of different materials, most often pine and spruce. In the production of such a beam, gluing of lamellas from different wood by pressing is performed. This allows you to get the finished product with the specified strength parameters. However, such a manufacturing process greatly increases the cost of production, and although in the final version the construction of glued beams is very strong and durable, the cost of its construction will not pay off too quickly.

Spruce and pine timber involves processing against:

- rot;

- the sun;

- moisture

- pests.

Size calculation

The optimal dimensions of the greenhouse are such dimensions (L × W) - 6 × 3 m. For them, we will calculate.

Timber greenhouse 50 × 50

A beam of 50 × 50 mm is most often used for the construction of greenhouses. But in this embodiment, the construction can not do without a beam of 100 × 100 mm: it is used for supporting supports and for the contour of the greenhouse in order to increase the strength of the structure.

With the dimensions of the greenhouse 6 × 3 m, there should be 4 load-bearing beams and 14 stiffeners (5 on the side faces and 2 on the end faces). There should also be braces - this is another 8 bars, two on each side. More bars are needed to create the upper and lower ligament of the greenhouse. The roof is made of boards and battens.

As a result, for such a design it is necessary:

- bar 50 × 50 mm - 142 m;

- corner 50 × 50 mm - 12.6 m;

- board 150 × 30 mm - 30 m;

- rail 40 × 20 mm - 100 m;

- bolts, nuts, washers d = 8 mm - 18 pcs.;

- self-tapping screws - about 200 pcs.

Bar greenhouse 100 × 100

A beam of 100 × 100 mm has a double section in comparison with a beam of 50 × 50 mm, so it is able to withstand at least twice as much load. From this it follows that the number of stiffeners located in the side faces of the structure can be halved, leaving 2-3 pieces. In proportion to this, the number of rafters will decrease. The amount of other materials will remain unchanged.

Drawing up a drawing

Although the construction of a greenhouse made of wood is a relatively simple process, you cannot do without creating a drawing. It allows you to accurately calculate the dimensions of all parts so that there is no skew design.

Here is one of the popular circuit options:

Selection and construction of the foundation

So that the greenhouse can serve more than one year and it can be used even in winter, laying the foundation is necessary. Since the weight of the structure itself is not too large, it is advisable to use a columnar or strip type of foundation.

Columnar is most often used if the area of the greenhouse is small. It can be made of concrete blocks, concrete pillars or bricks. When installing the supports, it is necessary to carefully monitor that they all stand strictly perpendicular to the ground. Their height also needs to be adjusted in level.

Important! The number of pillars of the foundation should coincide with the number of racks of the greenhouse.

The tape type is structurally more complex. It requires large expenditures of materials and time, so it is advisable to use it for greenhouses with a larger area.

Detailed column foundation technology:

- On the selected site for the construction, markup is carried out and the territory is cleared. If possible, the place is leveled.

- In the places where the supports will be located, they put marks.

- With the help of a hand drill, pits of the required depth and width are pulled out in these places.

- In each hole is placed on the beam as a label. All must be the same length.

- The upper edge of the timber defines the foundation horizon.

- A brick is laid in a hole with a column, concrete blocks or a whole concrete pillar. Their height should correspond to the height of the mark.

The technology of creating a strip foundation:

- At the selected place, a platform is prepared (leveled, cleaned of debris).

- The plot is marked in accordance with the dimensions of the greenhouse.

- A trench is dug along the contours with a depth of 0.3 m and a width of 0.3–0.35 m.

- The bottom of the trench is lined with a 10-centimeter layer of sand.

- Using the board (2 mm), formwork is installed - so that it rises 0.25 m above the soil. Boards are connected by couplers.

- Using the water level, note the level of foundation pouring.

- Between the boards install reinforcement (d = 5-6 mm) in increments of 0.2 m.

- The trench is poured with concrete and leveled.

- The foundation freezes 2-3 weeks.

Important! If the weather is hot, concrete needs to be moistened from time to time so that it does not crack. After removal of the formwork, waterproofing should be carried out.

Frame Installation Steps

The frame assembly process looks something like this:

- Sawing a bar into pieces of the required length.

- Sawing the edges of the joining beams at an angle of 45 °.

- Base assembly.

- Screwing parts of the frame to the base.

- The implementation of the upper strapping.

- Assembly and installation of truss pairs.

- Mounting the roof ridge and wind boards.

- Preparation of door and window openings.

Fasteners

The frame of a wooden greenhouse consists of supports for the roof, supports, columns, upper and lower trim. All this is connected using fasteners.

The following components are used:

- bolts

- anchor;

- long nails;

- supports for timber;

- sliding supports for rafters;

- metal corners.

Installation of door and window structures

The door and windows into the greenhouse are installed in place of the openings prepared for them. The door is always located at the end of the structure, the windows can also be located on the sides. It is best to install them on the south side so that when they open, warm air always enters the greenhouse.

The installation process looks like this:

- On the frames and openings, the marking of the hinge is made.

- Hinges and handles are attached to the door and window frames using self-tapping screws.

- Frames are fixed on the openings.

- If necessary, adjust the loops.

Selection of cover material

The wooden frame of the greenhouse allows you to use various options for covering material:

- Film. The most economical option, but it is suitable only for seasonal greenhouses, and not year-round, as it does not protect against frost and can easily break under the weight of snow. Its fastening occurs with the help of rails and self-tapping screws or a construction stapler.

- Polycarbonate. The most practical variant of the covered material is that it transmits light well and retains heat. Its cost is slightly higher than the film, but the service life is much longer. The greenhouse sheathed with polycarbonate is strong, but at the same time light. Its fastening is carried out using self-tapping screws with rubber gaskets.

- Glass. With the advent of polycarbonate, this option for covering the frame gradually recedes into the background due to its fragility and massiveness of the finished structure. In addition, it is not easy to install it - it is necessary to cut special grooves in the bars.

Did you know? In Iceland, the construction of greenhouses is carried out on geysers.

A wooden greenhouse is an excellent solution for year-round cultivation of vegetables in the garden: its installation is quite simple, material costs are not large, and the payback is quite high. With proper preparation of building material, such a design will last for more than one year.