Many gardeners with experience working with greenhouses dream of the industrial scale of growing vegetables. Of course, one or two small structures to make a profit will not be enough, it will require the construction of an industrial structure, which will be equipped with the necessary resources and equipment. How to build such a shelter will be discussed in the review.

What is the difference between industrial greenhouses and ordinary?

The main feature of industrial structures is their size. Professional greenhouses are hundreds and more times superior to ordinary ones. The area of such structures is measured in hundreds of square meters. Some industrial specimens are similar in shape to standard cottages and significantly elongated, but their length and width are much larger.

Did you know? The most unusual greenhouse is located in Brussels, near the Laken Castle. In this place there is a whole complex of greenhouse buildings with an area of 25 thousand m². The construction was erected in the XIX century on behalf of the King of Belgium Leopold. In addition to standard greenhouses, the complex includes a church and a dome chapel.

Others have a quadrangular shape with almost even sides - several elongated structures are built closely, but do not have walls between themselves. As a result, a gigantic agro-technical building is entrusted, the area of which is already measured by more than one thousand square meters.

Another difference is the purpose. Country greenhouses are created to increase productivity and supply their family with healthy vegetables. Professional options are built to generate income from growing crops for sale. Industrial greenhouses are distinguished by a strong frame. With huge sizes, the load on them increases (lining, snow, etc.). In addition, professional greenhouses without fail have a foundation.

The benefits of such greenhouses

- The use of industrial greenhouses has several advantages:

- availability of adequate resources;

- the ability to grow a large number of crops;

- large scope.

Preparation for the construction of an industrial greenhouse

Before starting construction, several important procedures should be followed.

Site selection and preparation

In order for the greenhouse to give the expected effect, it needs to be positioned correctly. The construction site should be flat. The maximum allowable slope is 0.04%. If hurricane winds are not uncommon in the area, additional shields and fences are built that will reduce the speed of gusts. They will be able to protect the structure from inflatable snow drifts.

Important! The ideal direction of greenhouses for the southern regions is from north to south. In cold areas, greenhouses are routed from west to east.

In case of heavy rainfall or during the melting of snow, water should not stagnate on the ground, which will erode the foundation and flood the greenhouse. You should also take care of providing the future structure with water. It is equally important that the soil is fertile. To obtain a plentiful harvest, it is necessary to plan the use and storage of soil mixtures and fertilizers.

Sizing and designing

Before proceeding with the construction, it is necessary to draw a drawing with the intended parameters and draw up a diagram.

Typically, projects consist of the following stages:

- The type of construction is determined. At the same time, the quality of the base, the heating system, the thickness and type of the skin of the frame, the location of the window leaves and the type of profile are also considered.

- Further on the drawing, the connection points of all parts are marked. At the same time, it is taken into account by which the installation will be carried out.

- A heating system is being developed. At this stage, it is thought over what kind it will be and a plan for its placement is outlined.

The working drawing is recommended to be performed in several displays:

- Foundation. Image from above, front and side.

- Greenhouse. Plan front, side and top.

- Heating mechanism and boiler. The projection from different angles.

Important! When constructing large greenhouses, the requirements of SNiPs, as well as wind and snow loads in the region, should be taken into account.

Step-by-step instructions for creating an industrial greenhouse

At first glance, building an industrial greenhouse is an overwhelming job. But, knowing all the subtleties and stages, everyone can deal with this matter.

Creating the foundation for the greenhouse

So that the design lasts a long time, and your costs are not wasted, it is mounted on the basis. Such a foundation will make it possible to firmly fix the structure, prevent precipitation from entering from outside and protect the soil from weeds.

For industrial greenhouses use the following types of foundation:

- Brick. It will serve for a long time, but the cost of such a foundation will be impressive. For the construction of the base will have to build a waterproofing pillow, which will prevent the negative impact of the soil. With this masonry, additional cement and sand will be needed.

- Stone. Natural stone is a great option. It is laid on a solution of clay and sand. The main drawback of this foundation is the presence of the necessary skills to work with stone.

- Tape. The most durable and reliable option in capital construction. For its construction, a sand cushion is equipped, and a boardwalk is also assembled and poured into a depth of 0.5 m with a solution. Width - 30-40 cm.

Important! When constructing the tape base, you must first equip the filling of fences for beds.

After pouring the foundation, it is tied. To do this, take a shaped pipe or corner made of metal. The harness is attached to the base with anchor bolts. An important requirement is a thorough painting of metal pipes.

The choice of material for the frame

An important element for both year-round and seasonal greenhouses is the frame.

Today, a large number of raw materials are used for the production of frames:

- Metal. The main material for greenhouse buildings. Differs in high durability and reliability. As a disadvantage, there is a high risk of corrosion. In the absence of control, such a frame can quickly become worthless.

- Wood. The cheapest option, which has both its pros and cons. It is used mainly in home-made versions, manufacturers on an industrial scale do not use it. The service life of this design is small and the strength is constantly changing. As a rule, such a frame can survive 3-5 years.

- Galvanized steel. The best option for protective structures. Among the advantages note low cost, stability, durability. On an industrial scale, frames today are made of this material.

- Aluminum. Such frames will be of interest to those who are guided by the experience of Western landowners. This material is not susceptible to corrosion and lasts a very long time. But, in comparison with galvanized steel, the price and softness of aluminum are much worse.

- Plastic. Gradually replaces all other materials. Plastic frames are easy to install and do not have a high cost. However, the strength of the material is inferior to metal.

Did you know? In Iceland, greenhouses are equipped with geysers. There is even such a sign: I saw a greenhouse, which means that there is a source of hot water nearby.

There are 3 forms of frames:

- arched or arched;

- gable;

- lancet.

Mounting and mounting the frame

After designing, laying the foundation, choosing the shape and material for the skeleton, you can proceed to the installation of the profile itself. Work is carried out only after the foundation dries well.

Stage of installation of the frame:

- The lower binding is performed. After that, vertical racks are installed and make the upper harness.

- According to the project and drawings, a roof frame is equipped. Since the height and perimeter of the structure will be rather large, several retaining posts are made.

- Corresponding fastenings (rubber washers, self-tapping screws, etc.) the skin is attached to the structure.

- At the edges of the covering material is glued with tape. It is important that cold air does not enter the structure through cracks.

- A few window leaves are made in the casing. They are needed to ventilate the greenhouse. Moreover, each structure should be easy to open and close.

Frame cladding

In Russia, it is customary to cover industrial greenhouses with film, glass or polycarbonate. Each of these materials has its pros and cons.

Polycarbonate

Universal material, resistant to external factors, durable and heat-resistant. In addition, this material, unlike glass, has a low price. Polycarbonate sheets easily bend, which is important for arched options for greenhouses.

- This material combines all the good qualities of glass and film:

- elasticity;

- durability;

- strength;

- tolerance of temperature differences;

- high thermal insulation;

- good light transmission;

- undemanding to leaving.

Glass

Durable but expensive material. Glass constructions can last for decades. The main plus is excellent light transmission. Even after decades, this material does not become cloudy and does not lose its transparency.

- Among the shortcomings note such characteristics:

- heavy weight;

- fragility;

- mediocre insulation.

Film industrial greenhouses are not effective, because polyethylene is not a strong and durable material.Important! The frame and foundation for glass cladding must be strong and heavy, which leads to an increase in construction estimates.

Engineering systems

For the successful cultivation of vegetables, it is necessary to organize a stable microclimate in the building. To do this, devices are installed in the greenhouse that maintain optimal humidity, temperature, and also provide lighting and fresh air.

Heating system

For those who need to grow vegetables all year round, information on heating a greenhouse is useful. It can be gas, electric or stove.

According to the type of heat supply, these types are distinguished:

- Steam. It functions by supplying hot water to radiators, which are located around the perimeter of the structure. Instead of radiators, pipes can be laid underground. In this case, the fertile layer will serve as one large radiator.

- Aerial. The heating system is connected directly to the ventilation. When you turn on the room begins to circulate warm air. The most budgetary, but ineffective option.

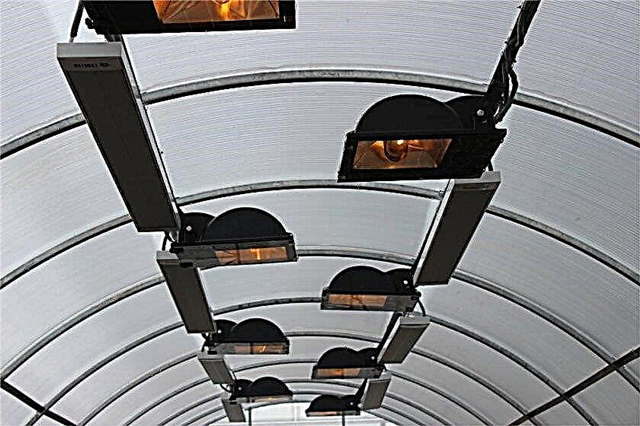

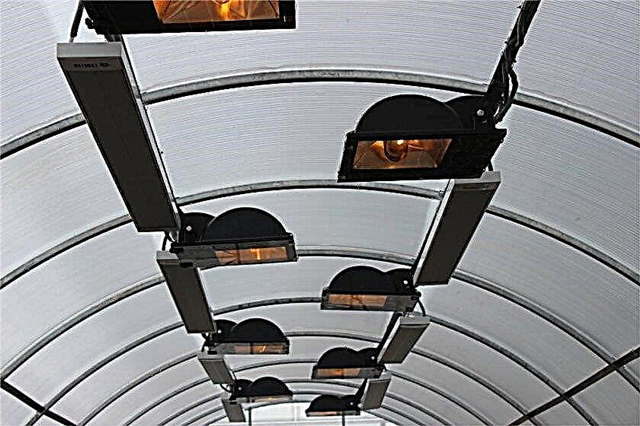

- Infrared lamps. Large greenhouses are best heated in this way. After all, infrared rays warm not the air, but the soil. The disadvantage of this system is the cost of equipment and the amount of energy expended.

Ventilation system

Air exchange is important for many cultures. Due to ventilation, excess heat and moisture are removed from the shelter, and oxygen and carbon dioxide are also exchanged. Air exchange is ensured by natural and forced ventilation systems. As a rule, special openings (windows, vents) are equipped in the roofs and walls of greenhouses. You can close the vents both manually and with the help of an automatic drive. For additional ventilation, fans are installed on opposite sides of the greenhouse.

Important! The higher the ventilation hole, the more efficient the air exchange process is: warm air rises independently, while lowering the fresh, cooler air.

Greenhouse lighting systems

Auxiliary lighting is especially relevant in winter, when daylight hours are very short. The most economical option in terms of energy intensity is the installation of LED lamps. Electromagnetic waves do not heat the air around, but the soil. But such equipment is not cheap. Sodium mirror phytolamps have proved to be quite good, but their acquisition will fly into a pretty penny.

Irrigation system

The own greenhouse needs to be equipped with irrigation. There are two main systems: drip and sprinkling. When sprinkling in a greenhouse, sprayers are installed that will water the plants from above, dropping on the ground with drops. As a result, plants receive the required amount of moisture at the lowest water consumption.

The sprinkler system may consist of several types of plants:

- stationary equipment fixed under the arch;

- fixed between the rows of the installation;

- mobile devices fixed to the ceiling.

The advantage of this method is that everyone can independently organize free drip irrigation using old hoses or tape. It is advisable to put water filters in professional hotbeds. This will not only save water from unwanted impurities, but also increase the service life of the equipment.

Planning of beds and arrangement of the greenhouse

After the construction of the greenhouse is completed, you can begin to plan the location of the beds.

There are 3 main types:

- Standard narrow rows. Between them space is provided for the movement of people or vehicles.

- Multilevel beds or racks. This option allows you to effectively operate the interior of the greenhouse. Plants are located one above the other on different tiers so that the upper bushes do not block the light from the bottom. This layout is used mainly for growing seedlings or strawberries.

- Hydroponics. In this case, there are no rows - the plants are grown in an artificial basis (water mixtures, porous structures, etc.), and they receive food during irrigation. This method allows you to shoot a good crop with minimal cost of water and nutrients.

Did you know? According to some reports, the first greenhouses appeared in ancient Rome. True, they are not much like modern ones. Gardeners planted bushes on small carts with soil, which they transported to the sun during the day, and drove them into cover for the night.

How to choose the right industrial greenhouse from the manufacturer

When choosing an industrial version of a greenhouse, it is important to proceed from the types of crops that you plan to grow, as well as the seasonality of exploitation and the volume of future crops. In this case, you should turn to trusted manufacturers who have established themselves in the market as quality performers. But the choice of the company is not a complete business. The effectiveness of the future greenhouse also depends on the technologies used. Therefore, when ordering a design, you should familiarize yourself with the practicing methods.

It is quite possible to build a reliable and attractive greenhouse on your own. The main rule: to develop a project, drawings and clearly follow the schemes. A well-established installation will last a long time and provide a good harvest all year round.